Our Products

At Indiana Drives & Automation., we are offer following products.

General Purpose AC Drives

BL5X AC VARIABLE FREQUENCY DRIVES

KEB Make F5 Application/ Servo Drives

F5-Multi Drives (Rating upto 900kw)

KEB Make Advance Smart Servo Drives S6/F6

KEB COMBIVERT S6 / F6 Intelligent Servo Drives

KEB Make Modular Drives for Multi Axis Servo Control:H6 (MultiAxis Drives)

The modular drive technology: KEB COMBIVERT H6

KEB F6K Series Servo Drive

KEB COMBIVERT F6-K - Power Range

KEB P6 Pitch Control Drive

Pitch and Yaw Drives for Wind Turbine Generator

KEB Make Smart C6

Programmable Multi Axis Controller

Synchronous AC Servo Motors

For cyclic applications demanding accurate positioning

The major MEP Products include

A) General Purpose AC Drives: BL5X AC VARIABLE FREQUENCY DRIVES

In most industries that use motors for machinery, there is a need for automation to achieve higher productivity, improve overall equipment efficiency, and save energy. This is achieved by interfacing motors with AC Variable Frequency Drives that can vary the speed and torque of the motor to meet the application demand, besides reducing starting current kick and providing protection to the motor.

Many customers prefer a combination package of motor and Variable Frequency Drive. It also ensures a single window for installation support, on-site service, repair, product training, and provision of spares.

We introduced BBVERT BL5X compact vector-controlled AC VFDs that offer excellent reliability and superior performance. BL5X 415VAC, 3 Phase Drives are available from 0.4kW (1HP) to 110kW (150HP). For very low power applications, BL5X Single Phase 230VAC series is available from 0.2kW (0.25HP) to 3.7kW (5HP).

BL5X drives can be used for a variety of applications - fans, blowers, pumps, mixers, plastic machinery, conveyors, textile machinery, packaging machinery, and more. Both BL52 and BL50 Drives are available with Indiana Drives & Automation.

BL52/BL50 AC VFD RATINGS AND SALIENT FEATURES:

- BL5X VFD Ratings: 0.4kW to 132kW (1 HP to 150 HP) (3 Phase 400Vac class)

- High-speed Pulse input (50kHz) & Pulse Output signal (32kHz)

- Built-in Modbus Communication protocol

- BL5X VFD Ratings: 0.2kW to 3.7kW (0.25 HP to 5 HP) (1 Phase 200Vac class)

- IP20 Enclosure (Fan cooled)

- Built-in Brake Chopper up to 30kW for BLX VFD (Above 30kW-optional Brake Unit)

- Drive Protections: Drive Output Short circuit, Under Voltage/Over Voltage, Overload, Over Temperature, Ground Fault, Current Hunting Prevention, Stall Prevention

- Control Mode: V/F & Sensorless Voltage Vector Control (SVVC)

- Built-in PID Control, Torque Boost Function, Speed Search Function, Speed Skip Function

- Excellent Starting Torque: 150% @ 0.5Hz in SVVC Mode/150%@1.5Hz in V/F mode

- AC/DC Input Choke: optional (Recommended for Drive Protection & THD Reduction)

- 16 Preset speeds with Timer functions for multispeed profile

- Brake Resistor for Dynamic Braking: External Option (ratings depend on application)

- Scope Function to assist in commissioning, troubleshooting, and diagnosis

- CE Certified and Compliance with EU RoHS Standards

B) KEB Make F5 Application/ Servo Drives: F5-Multi Drives (Rating upto 900kw)

Open-loop and closed-loop drive controller for synchronous servo motors and asynchronous motors…

- Wide power range for 230 V / 400 V & 690V connection

- Either AC or DC connection

- Optimal characteristics at the motor shaft in different application areas with KEB-SMM (Sensorless motor management)

- 29 plug-in control terminals, PNP- / NPN logic switchable

- 2 analog inputs 0 … 10 V, ±10 V, 0 / 4 … 20 mA

- 2 programmable analog outputs 0 … ±10 V

- 8 programmable digital inputs

- Programmable outputs: 2 x relay, 2 x transistor

- 4 programmable software inputs/outputs

- 8 free-programmable parameter sets including S-curves, ramp stop, power-off function, DC-braking, PID controller, electronic motor protection, brake control, internal counter input, output frequencies up to 1600 Hz, output voltage control, switching frequencies up to 16 kHz, output phase monitoring, energy-saving function

- Scan time of the control terminals in 2 ms-time pattern

- ± DC-link connection, motor-PTC evaluation, hardware current limit

- Internal brake chopper (series up to housing size G, option from housing size H)

- Controlled positioning to end position/counter pulse

- Optional: execution in accordance with EN 954-1 protection category 3: protection against unintended restart

The frequency inverter KEB COMBIVERT F5 Multi is equipped with all functions and characteristics and furthermore especially prepared for closed-loop operation. Very flexible because of plug-in feedback cards:

- Resolver

- Incremental encoder, initiator

- Sin/Cos encoder

- Absolute encoder

- Hiperface,

- EnDat

- BISS or Tacho

Decentralized automation in the drive actuator with standard functions relieves superior control systems and create clear, compact programs.

- speed and torque control

- position control

- synchronous speed control

- electronic gear or customer-specific solutions such as

- cam switch - rotary table positioning

- register function - contouring control

- single-axis positioning

Applications:

- Plastic (Injection/Blow molding machines for servo pumps)

- Plastic all-electric Injection/Blow molding machines

- Plastic extrusion m/c (Pipe & blown film plants)

- Plastic recycling machines & Thermoforming m/c

- Machine Tools (SPM’s, High-speed spindles, CNC mc)

- Packaging machines

- Steel & metal (Flying shear/continuous shear)

- Metal (Wire drawing machines/ Slitting machines)

- Test benches (for testing gearboxes, pumps, motors etc).

- Textiles machines (Ring frame/ flatbed printing/ Sizing/Draw frame/ Texturizing/Dyeing m/c/Laundry machines….)

- Crane & material handling

- Storage & retrieval system

- Elevators (including PMSM motors)

- Fan/pumps/compressors (with pressure feedback control)

C) KEB Make Advance Smart Servo Drives S6/F6

KEB COMBIVERT S6 / F6 Intelligent Servo Drives

The COMBIVERT S6 / F6 servo system adds a compact, flexible, and powerful drive module to the KEB product portfolio for highly dynamic servo applications. The optimally selected KEB components are the key to this successful drive concept. At the heart, the innovative S6 Servo drive is offered in an attractive book-style format and offers real-time performance.

Powerful

- 0.75KW…5.5 KW in two enclosure sizes for S6

- 4KW …. 450KW in seven sizes for F6

- Book format for space-saving control cabinet configuration

- Direct connection to the mains for 230 V and 400-480 V grids,

- DC-input is also available, 260 ... 750 V

- Low leakage current mains filter

Motor Operations

- Universal control for asynchronous, synchronous, IPM, or Synchronous reluctance motors

- Motor operation with encoder feedback or encoder-less ASCL/SCL for precise speed control

- Motor temperature monitoring with PTC or KTY sensors

- Two-channel multi-encoder interface

- Integrated GTR7 brake transistor

- Integrated brake control and brake supply

Communication Options

- Real-time Ethernet-based interfaces (EtherCAT, ProfiNET, POWERLINK)

- RS232/485 for diagnostics or display

Analog & Digital I/O

- 8 digital and 2 analog inputs

- 2 digital and 1 relay output

- 1 Analog output 0 ... 10 V

- 1 brake control output

Integrated Functional Safety

- Safety function STO in accordance with ISO 13849 Performance Level e / IEC 62061- SIL 3

Applications

- Packaging Machines

- Machine Tool (SPMs)

- Textile Machinery

- Spindles and Woodworking Machines

- Plastic Machinery

D) KEB Make Modular Drives for Multi Axis Servo Control:H6 (MultiAxis Drives)

KEB COMBIVERT H6 is the new product family for multi-axis solutions with the following modular components:

- Power supply

- Active front end - power supply and regeneration

- Single-axis drive units

- Double-axis drive units

- 24 V DC-supply unit

- Embedded IEC 61131-3 control unit

- Fieldbus adaptation

- Multi-encoder-interface

- 24 V brake control

- Integrated safety system

Features and benefits at a glance:

- Space-saving design of a multi-axis drive system

- Load share via protected DC bus link

- Significantly reduced wiring and installation

- Integrated Soft-PLC-, Motion- and NC- control

- Integrated 24 V DC supply

- Standardized connection technology simplifies handling

- Integrated two-level safety systems

- Innovative central cooling solutions for heat dissipation outside the control cabinet

- Improved quality and lifetime by means of active DC bus capacitor cooling

- Central operation concept for the complete system

- Standardized programming tools with diagnostics

Applications:

- Plastic All Electric Injection/Blow molding machines

- Electronics Line Shaft for printing machines

- Machine Tools (SPM’s)

E) KEB F6K Series Servo Drive

KEB COMBIVERT F6-K - Power Range

The device features a particularly compact design and has been optimized for the use of individual machine axes and equipment. KEB COMBIVERT F6-K covers the power ranges 1.5 kW to 900 kW. KEB COMBIVERT F6-K frequency inverters follow the principle ONE FOR ALL. Capable of functioning as a Closed-loop drive without a separate feedback device in the following operating modes:

- ASCL - Sensorless control of asynchronous motors (induction/squirrel cage) (Asynchronous Sensorless Closed Loop)

-

SCL - Sensorless control of synchronous motors permanent magnet including a universal feedback card, the KEB COMBIVERT F6-K adds:

- FOR field-oriented control of asynchronous motors with encoder feedback

- Closed-loop servo motors and open-loop operations with enhanced features.

- All operating modes are selectable by software.

Control units

A new generation of high-performance 32-bit microcontroller provides universal internal and external control functions such as:

- Speed control - current control grid 125 us

- Torque control - speed controller 250 us

- Internal positioning module - bus cycle < 1 ms

- Position mode - digital input scan: 250 us

- External supply 24 V DC - analog input scan: 250 us

- Motor adaptation with standstill position detection

- Analog input modes: 0 … +/-10 V

- Switching frequencies up to 16 kHz 0 … +/- 20 mA, 4 … +/- 20 mA

The 2-channel STO safety function and all analog and digital I/Os, including the CAN interface, as pluggable connections.

Universal feedback interface

The KEB COMBIVERT F6-K provides excellent flexibility for control tasks. The control card contains two input channels that support the following sensor types:

- Resolver

- Incremental TTL encoder

- BISS

- SSI

- SinCos

- Endat 2.1 and 2.2

- Hiperface

Preassembled cables, suitable for stationary or flexible applications, make installation easy and minimize wiring faults.

Download Product Catlog F6F) KEB P6 Pitch Control Drive (Pitch and Yaw Drives for Wind Turbine Generator)

A pitch drive is used to adjust the rotor blades and regulate the power transmitted to the mechanical system. A more responsive pitch system allows the turbine to better react to constantly changing conditions. This puts less stress on the mechanical system and ultimately provides a better performing, longer-lasting wind turbine. The yaw Drive is used for positioning the Nacelle of the wind turbine.

BBL-KEB provides a complete solution consisting of Pitch & Yaw Drives, PLC controller, Servo Motors with Brake & encoder, Cabinet with special design, and Energy storage using an ultra-capacitor bank for wind turbines. The cabinet is specially designed for temperature endurance from -30°C to +60°C.

Key features of BBL-KEB pitch-yaw drive system are:

- Small footprint – Innovative heatsink allows for a smaller cabinet and cost savings.

- Rugged design – Wide temperature ranges, special shock-resistant features, etc.

- Dynamic response – Latest control technology provides the best pitch response.

- Powerful programming environment – Programmed in accordance with IEC 61131-3.

- Flexible communication – RS232 serial (user-defined), ModbusTCP, option cards: Profibus, CANopen supported.

- Integral RFI filter – Robust electrical system.

- Precise Position Control – Flexible feedback interfaces; Including absolute SSI.

- Single source – System components are optimized to operate together.

- Integrated safety features – e.g., switchover to encoderless operation in case of encoder loss.

- Features as required – Braking resistor, fieldbus communications, 24VDC supply, battery monitoring, etc.

G) KEB Make Smart C6: Programmable Multi Axis Controller

KEB COMBICONTROL C6 is the new line of motion control solution, focused on high dynamic drive-oriented applications. For example, wire drawing machines or bar mills with multi-stand configurations need precision in tension regulation; all require a component in the integrated solution that can achieve these functions and communicate at high speed with the drive downstream and upstream to the PLC.

KEB provides the C6 controller, which completely fulfills this need. Based on the integrated EtherCAT master protocol, the KEB Combicontrol C6 offers high-speed serial communication for multi-axis operation with inverter drives or servo drives. C6 also offers a variety of Digital as well as Analog I/O’s connected on the fast EtherCAT serial bus for faster data acquisition and control.

- Programming IEC61131-3 software with utilities offered by CoDeSys V3 core

- Drive bus connection over EtherCAT for multi Axis control

- Field bus communication

- Simple connection for remote I/O components

- Also available in Box IPC’s and Panel IPC’s for high integration of control and visualization

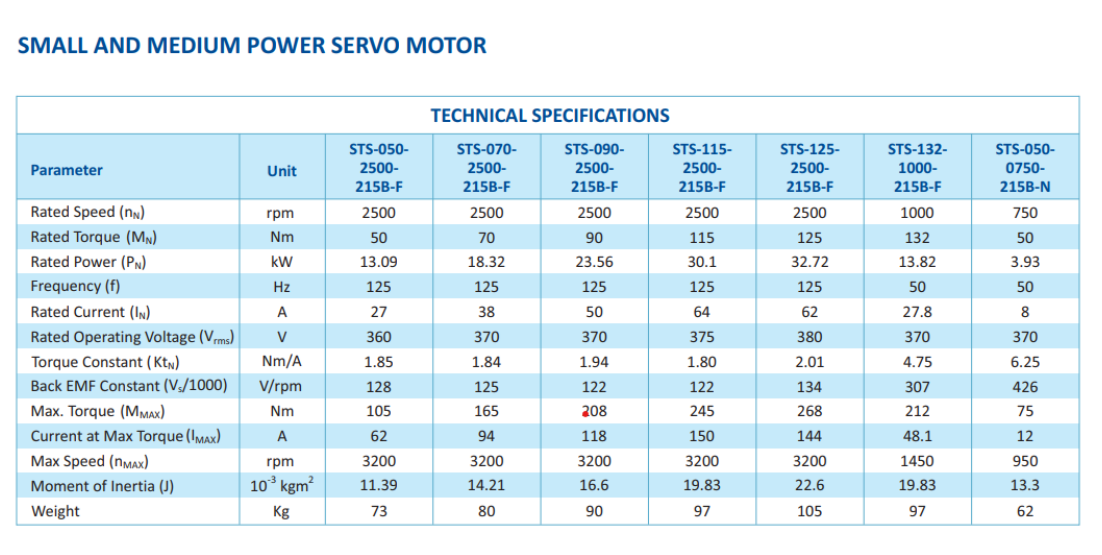

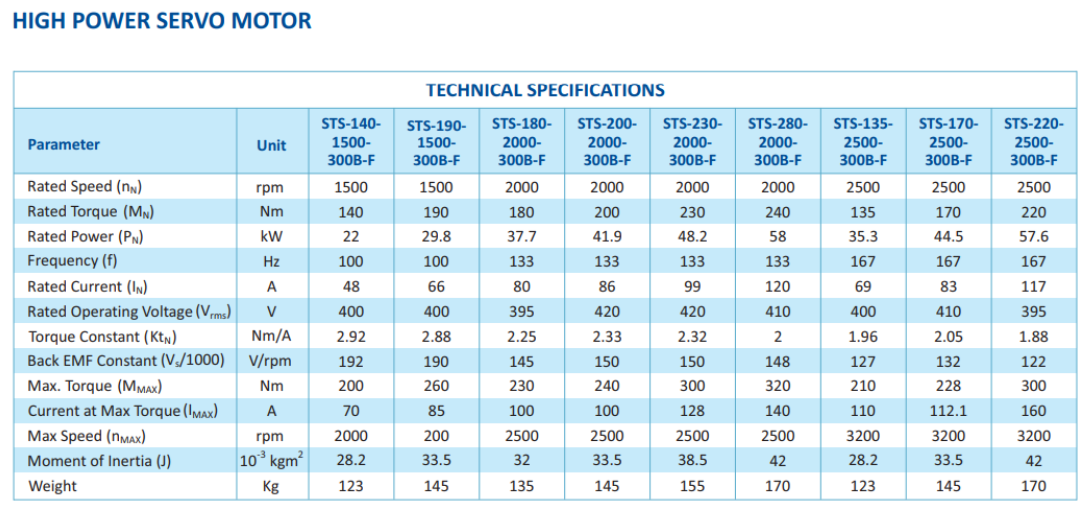

H) Synchronous AC Servo Motors

For cyclic applications demanding accurate positioning:

- Torque Ratings: 50Nm to 280Nm

- Power Ratings: 13kW to 58kW

- Maximum Speed: 3200rpm

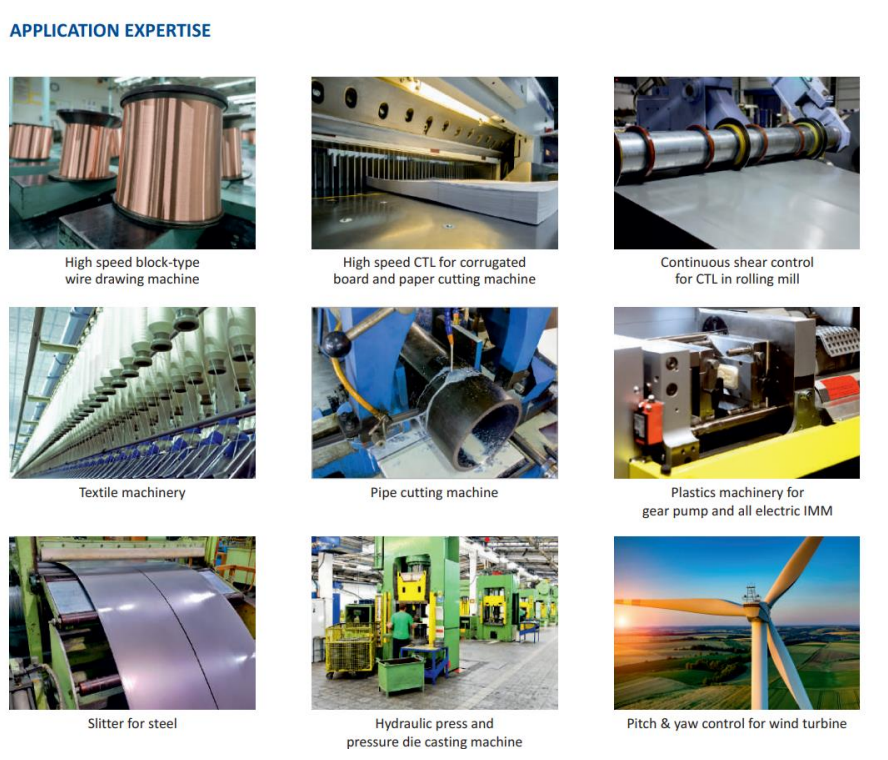

I) Machine Applications

Applications:

-

KEB drive solutions are ideal for:

- Plastics Machinery: All types of extrusion machines, shredders, injection molding machines including All Electric Injection molding machines, Hybrid machines...

- Textile Machinery: A wide variety of textile machines such as OE Spinning, Ring frames, Carding, Clothes manufacturing...

- Elevators and Cranes: All types of high-performance vertical motion systems including passenger and freight elevators, hoists, erection cranes, gantries...

- Motion Control: Variety of Industrial Automation machinery demanding speed, torque, motion control, multi-axis positioning control...

- Compressors and Other Applications: Screw compressors, steel rolling, industrial and HVAC fans and pumps...

- Steel Rolling Mill: Continuous Shear Control along with Servo for shifter, Cut To Length line control...

- Wind Mill Application: Continuous Wind Mill Pitch and Yaw Control...

-

DC Drive Solutions are ideal for:

- Sugar Centrifuge Machine: All capacities of batch-type Sugar centrifuge machine control with trip-free operation and fastest commissioning time...

- Start/Stop Shear and Stand drive for Bar Mill: Bar Mill Start/Stop flying shear control up to bar speed of 18 MPS and offering very good parking position accuracy. This drive is also used for DC continuous stands, Pinch Roll, Tail breaking rolls...

Need Anything ?

We’re Here to Help. Connect with us.